HOW IT WORKS

Achieving deadlines has never been easier. Ensure availability & preparedness long before beginning the production cycle.

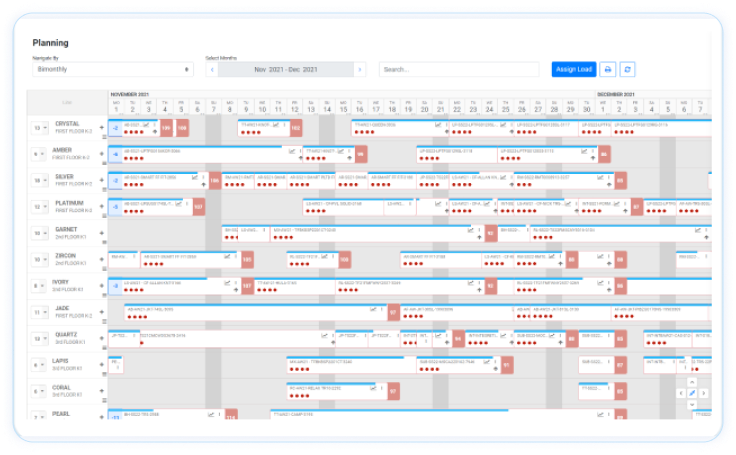

Integrated Planning Board

Highly visual and flexible “drag & drop” planning approach allows effective master planning across factories with fast, detailed & accurate scheduling of orders to production lines & machine.

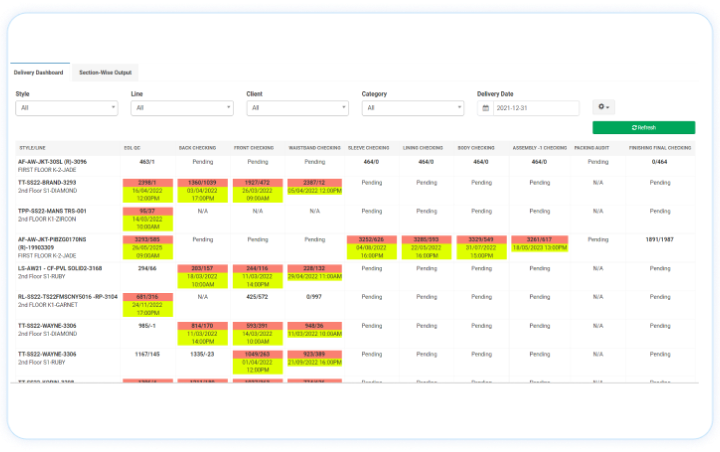

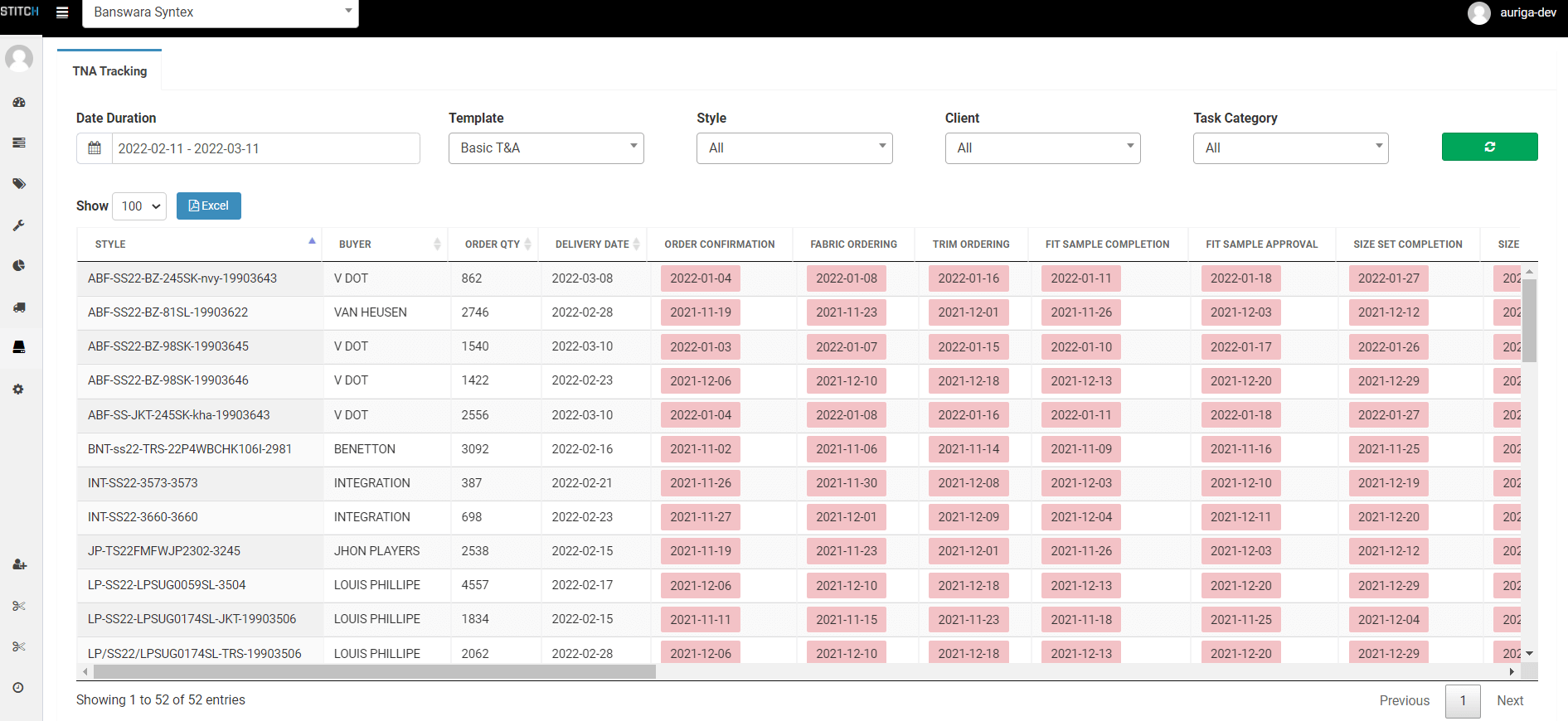

Dynamic Delay Alerts & Updates

Automatically calculate the impact of updates with color coded alerts supporting early proactive action & management by exception.

Dynamic Delay Alerts & Updates

Automatically calculate the impact of updates with color coded alerts supporting early proactive action & management by exception.

HOW IT WORKS

Achieving deadlines has never been easier. Ensure availability & preparedness long before beginning the production cycle.

Integrated Planning Board

Highly visual and flexible “drag & drop” planning approach allows effective master planning across factories with fast, detailed & accurate scheduling of orders to production lines & machine.

Dynamic Delay Alerts & Updates

Automatically calculate the impact of updates with color coded alerts supporting early proactive action & management by exception.

Dynamic Delay Alerts & Updates

Automatically calculate the impact of updates with color coded alerts supporting early proactive action & management by exception.

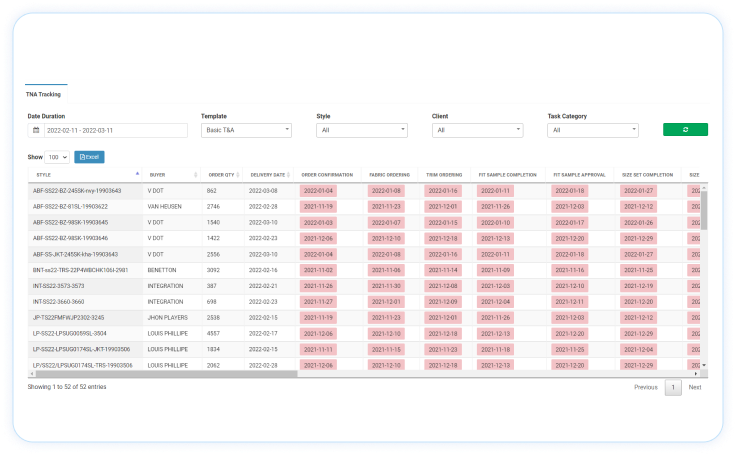

T&A

Track all pre-production tasks from order booking through approvals to ensure departments have clear priorities & everything is ready for the production on time.

FEATURES

An extensive suite of capabilities necessary to cost-effectively manage quality issues

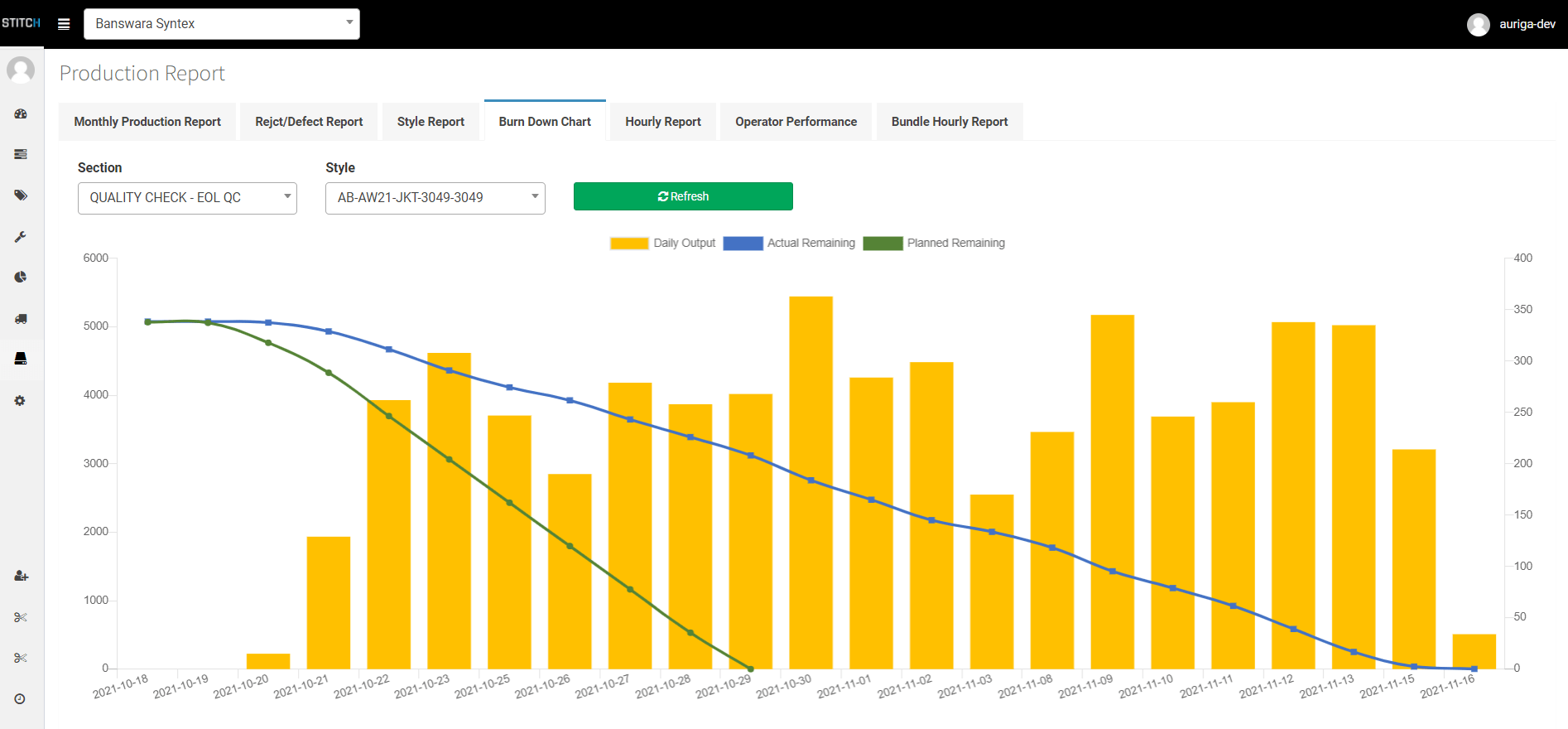

Capacity Planning

Provides fast and realistic planning of total demand & capacity at factory and production level across multiple production processes.

Line Planning

Sequencing & allocating orders to various product lines as per the product setting to understand daily production targets for a line.

Critical Path Management

Construction of project model by listing down the task requirement, dependencies in-between and time estimation to manage the critical path and taking necessary actions.

Material Requirement Planning

For production planning and scheduling, know about the availability of raw materials and production requirements. This system can be handled manually or fully automated by software.

Master Production Schedule

It helps to schedule the particular material or product to produce in a given time. They are created by the software and customized by the user.

Process Planning ( Routing)

Target time and material consumption details. Build the baseline of estimated material requirements and calculation of the earliest possible delivery date.